Granite is mostly light flesh red, light grey, grey and white, which mainly depends on its mineral composition and content. Medium-coarse and fine-grained structure, block structure, there are also some for the mottled structure, spherical structure, seemingly gneiss-like structure, etc.. The structure of granite is relatively compact and not easy to absorb water. Usually the density of granite is between 2.6 and 2.8g/cm³, which is a kind of heavy rock.

Granite sand production is the process of crushing and processing granite into manufactured sand, and its process flow, equipment configuration, and technical points are as follows:

1. Process Flow

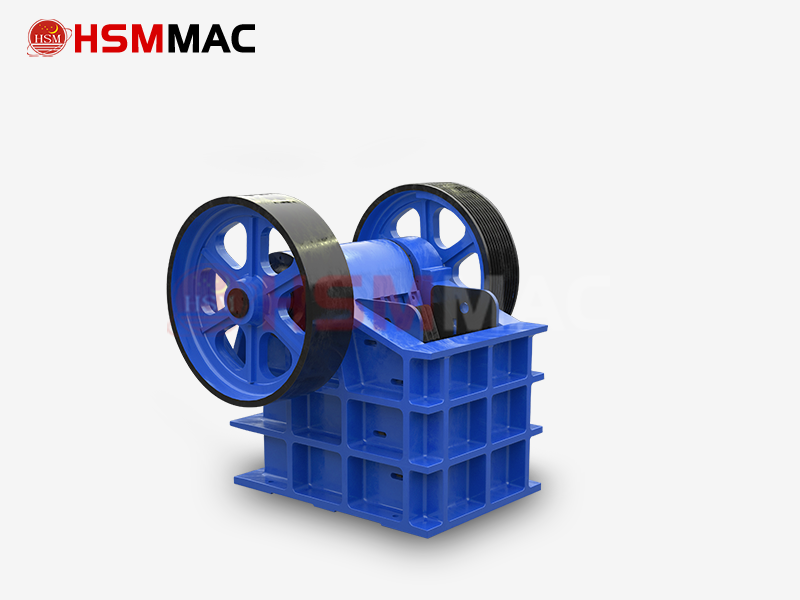

Coarse crushing stage: The raw ore is sent into the jaw crusher by a vibrating feeder for preliminary crushing, reducing large granite blocks to 100-300mm.

Intermediate crushing and screening: The material after coarse crushing is conveyed to a cone crusher (or impact crusher) for secondary crushing, and then sorted by a vibrating screen. The oversize material returns to the intermediate crushing equipment, and the undersize material enters the next stage.

Fine Material and Sand Making: The 0-20mm material enters the roller crusher for further crushing and is processed through cyclone dewatering and dehydration technology to obtain finished sand with a particle size of ≤4.75mm.

Washing and Dewatering: After being cleaned by the spiral sand washing machine, the sand material is passed through a dewatering screen and fine sand recovery equipment to remove impurities and moisture, resulting in clean finished sand.

Waste Water Treatment: The sand washing wastewater is separated from sludge through sedimentation tanks and belt filter presses, with clean water recycled and sludge compressed into sludge cakes for external transportation, achieving zero discharge.

2. Key Equipment Configuration

Coarse crushing equipment: Jaw crushers, suitable for crushing large granite blocks.

Medium crushing equipment: Cone crushers, used for secondary crushing, with output particle size of 20-40mm.

Sand making equipment: Roll crushers, suitable for open circuit roll grinding process, producing fine sand directly.

3. Typical configuration cases

Case: Using a jaw crusher + cone crusher + roller crusher, the material is crushed in three stages and then graded through a vibrating screen to produce finished products of 0-5mm, 5-10mm, and 10-20mm, suitable for high-grade engineering sand requirements.

4. Technical Advantages and Applications

Product quality: Mechanically produced granite sand has particles with many acute angles and low powder content, with a fineness modulus that can be adjusted (0.25-5mm), meeting the standards for construction sand. Environmental protection: The waste water recycling system and sludge press filter technology can achieve zero discharge of production wastewater, in line with the requirements of green mines. Application fields: Widely used in construction concrete aggregates, highway pavement materials, railway ballast, water conservancy projects, and landscape construction.