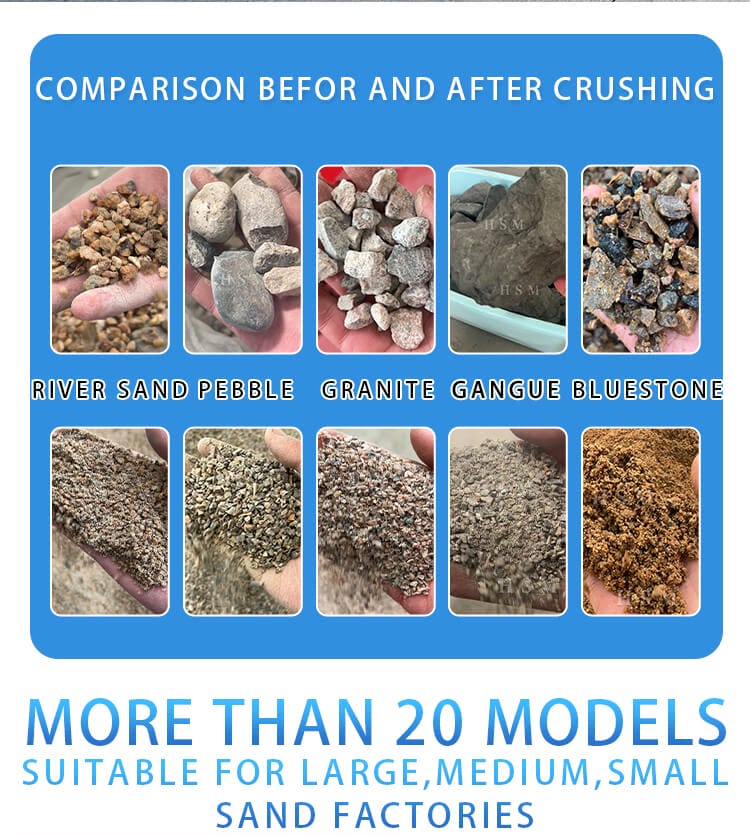

Applicable materials:Coal, River pebble, calcite, quartzite, marble, pebble, bentonite, iron ore, bluestone, mountain stone, water slag, limestone, weathered sand, diabase, granite, basalt and so on

Application scope: Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

The Plain Roller Crusher represents another breakthrough in the manufacturing of sand and aggregate production equipment. Also known as a dual-roll crusher or dual-roll sand maker, it utilizes two motors to drive dual rollers that crush and grind materials. It is suitable for fine crushing operations where the feed size is below 80mm and the final product size ranges from 50 mesh to 20mm.

The Plain Roller Crusher is a kind of machine which is extended by the spring roller crusher. The advantage of hydraulic structure is that it can control the pressure between two reliefs accurately. Long-term continuous operation can still guarantee the crushing pressure between two rollers. Therefore, the equipment of roller crusher in the grinding system can give full play to the production capacity of the grinding equipment. Generally, the output can be increased by 30%~40%, and the total energy consumption can be reduced by 20%-30%.

River pebbles, calcite, quartz, glass, marble, cobblestone, bentonite, iron ore, bluestone, mountain rock, limestone, weathered sand, diabase, granite, basalt, and other materials for crushing and sand-making.

The crusher is classified into small, medium, and large models:

1. Small Spring Models (2PGT series): 2PGT400×250, 2PGT400×400, 2PGT610×400. Hourly output: 2–20 tons. Ideal for small/medium sand plants.

2. Medium Spring Models (2PGT series): 2PGT750×500, 2PGT800×600. Hourly output: 10–50 tons. Cost-effective for new sand plants.

3. Medium Hydraulic Models (2PGY series): 2PGY750×500, 2PGY800×600, 2PGY800×800, 2PGY1000×800. Hourly output: 20–80 tons. Higher efficiency and automation.

4. Large Hydraulic Flagship Models (2PGY series): 2PGY1000×1000, 2PGY1200×1200, 2PGY1500×1000, 2PGY1800×1000, 2PGY2000×1000. Hourly output: 80–400 tons. Designed for large-scale plants with one-click operation.

1. Superior Product Shape: Minimal over-crushing.

2.Adjustable Discharge Size: Simple and precise control.

3.Non-Clogging Design: Optimized structure avoids blockages.

4.Dual Motors: Powerful and reliable.

5.High Durability: Rollers made of patented manganese steel for extended lifespan.

6.Cost-Effective: Low investment and operating costs.

1. .Superior to Hammer Crushers: No need for frequent replacement of vulnerable parts.

2. High-Quality Sand: Produces well-rounded sand particles with rational grading, low over-crushing rate, and high output.

3. .Advantages Over Hammer/Impact Crushers: Roller sleeves have an average service life of over 2 years.

4. Patented Technology: The high chromium manganese steel wear-resistant roller skin (national patent), precise discharge adjustment system (national patent), and roll design (national patent) ensure optimal performance.

|

Specification and model |

Roll diameter (mm) |

Feed size (mm) |

Productive capacity (t/h) |

|

2PGT400×250 |

φ400 |

≤25 |

2-10 |

|

2PGT400×400 |

φ400 |

≤25 |

5-12 |

|

2PGT610×400 |

φ610 |

≤30 |

5-20 |

|

2PGT750×500 |

φ750 |

≤30 |

10-40 |

|

2PGT800×600 |

φ800 |

≤40 |

12-50 |

|

2PGY800×800 |

φ800 |

≤40 |

40-50 |

| 2PGY800×1000 |

φ800 |

≤40 |

50-80 |

|

2PGY1000×800 |

φ1000 |

≤40 |

50-80 |

|

2PGY1000×1000 |

φ1000 |

≤40 |

80-100 |

|

2PGY1200×1000 |

φ1200 |

≤60 |

100-120 |

|

2PGY1200×1200 |

φ1200 |

≤60 |

120-150 |

|

2PGY1500×1000 |

φ1500 |

≤80 |

150-200 |

|

2PGY1500×1200 |

φ1500 |

≤80 |

200-250 |

|

2PGY1800×1000 |

φ1800 |

≤100 |

250-300 |

|

2PGY2000×1200 |

φ2000 |

≤120 |

300-400 |

+86-18703839693

+86-18703839693