Large, medium and small roller sand making machines are suitable for crushing and making sand of a variety of materials with medium hardness and below, including but not limited to limestone, river pebbles, cobbles, basalt, granite, sandstone, gypsum, gangue, dolomite, calcite, Shale, as well as some metal ores, cement clinker, construction waste, etc. Due to its wide material adaptability and particle size control flexibility, this type of equipment is often used in metallurgy, building materials, chemicals, refractory materials and other industries to meet the needs of various engineering projects such as highways, railways, high-rise buildings, and hydropower dam construction. Aggregate requirements.

The large, medium and small roller sand making machine is a widely used high-efficiency crushing equipment. It squeezes, crushes and makes sand from materials through two relatively rotating high-strength wear-resistant rollers. It is suitable for processing all kinds of medium-hard materials. It has a compact structure and small floor space, and can adjust the discharging particle size as needed to meet the needs of different sand and gravel specifications. The equipment is easy to operate, easy to maintain, has low energy consumption and moderate investment cost. It is deeply loved by the majority of sand and gravel manufacturers, especially playing an important role in small and medium-sized sand and gravel production lines.

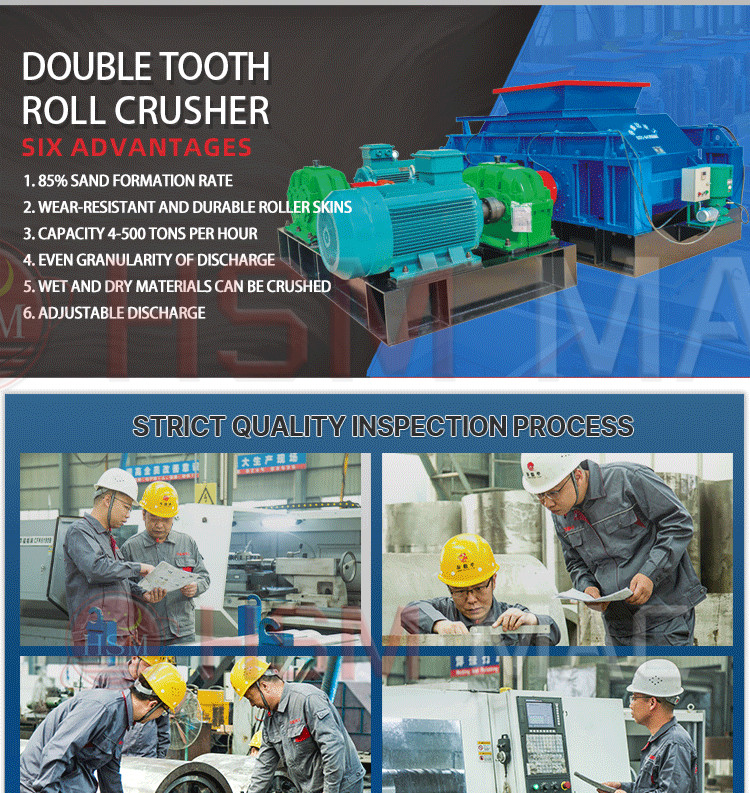

Henan Huashengming Heavy Industry is a large manufacturer specializing in the R&D and manufacturing of double-roller sand making machines. It is located in Henan Province, the hinterland of the Central Plains, and enjoys a superior geographical location and rich industrial resources. The manufacturer is committed to providing customers with efficient, energy-saving and environmentally friendly roller crushing and sand making equipment. The products cover a variety of models and are widely used in mining, building materials, chemical industry and other fields. With exquisite manufacturing technology, strict quality management system and perfect after-sales service, Henan Huashengming has won a good reputation and wide market recognition in the roller sand making machine industry, and is a trusted partner of many sand and gravel production companies. .

The reason why large, medium and small roller sand making machines are very popular in the sand and gravel processing industry is mainly based on the following key factors:

1. High-efficiency crushing and particle size control: The counter-roller sand making machine adopts the principle of counter-roller extrusion, which can efficiently crush various ores, rocks and other materials with moderate hardness, and achieve precise control of the discharge particle size by adjusting the distance between rollers. , ensuring that the sand and gravel grains are regular and well graded.

2. Strong adaptability: This type of sand making machine can handle a wide range of materials, including various materials with medium and low hardness. It is suitable for a variety of application scenarios in small and medium-sized sand and gravel plants, and is also suitable for some aspects of large sand and gravel plants.

3. Compact structure and flexible layout: Large, medium and small roller sand making machines are compact in design and occupy a small area. They are easy to install in various complex site environments and are conducive to production line layout and expansion.

4. Easy operation and low maintenance cost: The equipment operation interface is intuitive and easy to understand, easy for employees to use, and simple maintenance. Key components such as the roller skin are highly wear-resistant and easy to replace, which greatly reduces operation and maintenance costs.

5. Energy saving and environmental protection: New double-roller sand making machines are usually equipped with energy-saving motors and closed structures, which can effectively reduce noise pollution and dust emissions, and meet today’s society’s requirements for environmental protection and sustainable development.