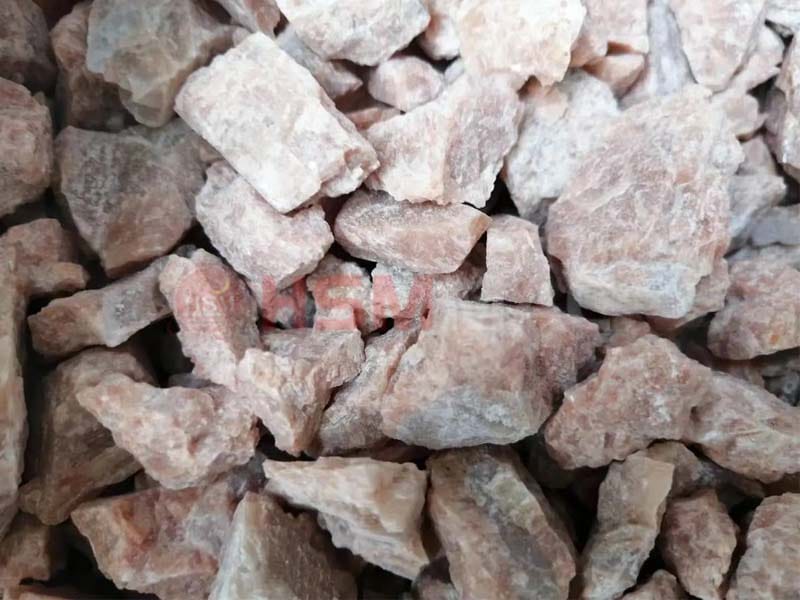

As an important non-metallic mineral resource, potassium feldspar has a wide range of applications in industrial manufacturing. Potassium feldspar crushing solution not only affects the production efficiency, but also directly related to the quality and cost of the product. This article will introduce the configuration scheme of potassium feldspar beneficiation production line in detail.

Potassium feldspar crushing equipment programme needs to be combined with ore characteristics, processing capacity, finished product size and environmental protection requirements for comprehensive design. The following is a summary of key equipment selection and process flow:

Core crushing equipment selection

Rough crushing stage

Jaw crusher

Jaw crusher: suitable for primary crushing of 700-800mm large ores, with the advantages of simple structure and low maintenance cost. Hydraulic Roll Crusher: Highly efficient crushing through high pressure roll extrusion, especially suitable for high hardness ores, can reduce dust generation.

Medium and fine crushing stage

Impact crusher

Impact crusher: Suitable for fine crushing operation, uniform size of finished products, suitable for 10-30mm finished product requirements.

Roll crusher: low energy consumption crushing through layer extrusion technology, reduce micro cracks, suitable for high purity potassium feldspar processing.

Auxiliary equipment

Vibrating screen: used to screen different size of ore, high frequency vibrating screen can effectively remove iron oxide impurities.

Magnetic separator: Separate the iron magnetic impurities, improve the purity of potassium feldspar.

Dedusting devices: such as microporous filters and collection boxes to reduce the escape of dust during the crushing process.

Typical Process Flow

Coarse crushing → medium crushing → fine crushing:

Jaw Crusher (coarse crushing) → Impact Crusher (medium crushing) → Roll Crusher (fine crushing) to ensure that the ore size is gradually refined to the target range (e.g. 10-30mm).

Screening and sorting:

After vibrating screen classification, magnetic separator removes iron impurities and acid washing equipment further purifies. Dust Removal & Collection:

Dust control is achieved by the use of airtight crushing boxes, dust covers and winch transport, combined with microporous filters and collection boxes.