Manganese ore crushing plant programme needs to be designed flexibly according to the type of ore, production scale and environmental protection requirements. It is recommended to adopt graded crushing + closed-circuit screening process with intelligent adjustment equipment (such as hydraulic cone crusher, roll crusher) to balance the efficiency and cost. For complex embedded ores, it can be combined with high-pressure roller mill or wet process to further improve the processing effect.

Manganese ore Crushing stage classification equipment selection

Rough crushing stage (particle size >200mm)

Jaw crusher

Recommended equipment: Jaw crusher (e.g. PE series)

Advantages: high crushing ratio (6-8), strong impact resistance, suitable for processing large raw ores. Hydraulically adjustable discharge opening (50-150mm) to adapt to different feed requirements.

Applicable scenario: high hardness manganese ore (such as hard manganese ore) or raw ore with high mud content.

Medium crushing stage (target size 2-50mm)

Cone Crusher

Recommended equipment: Cone Crusher

Advantages: Laminar crushing principle ensures even particle size, automatic overload protection in hydraulic system; processing capacity up to 100-800t/h.

Optimised design: short head type cone crusher is used for pre-treatment before fine crushing, reducing subsequent grinding load.

Fine crushing stage (target size 0.5-1mm)

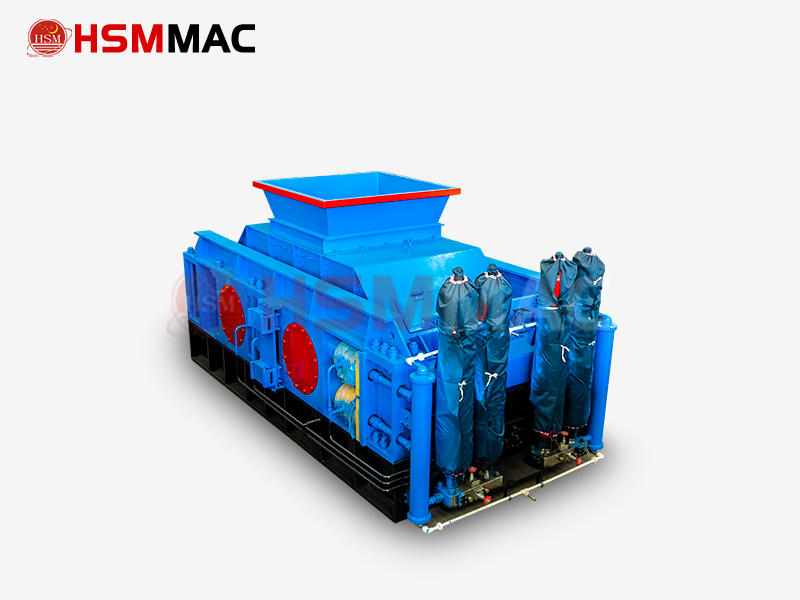

Roll Crusher

Recommended equipment: Hydraulic Double Roller Crusher

Advantage: Fine crushing is achieved by roll extrusion and shearing, with uniform discharge and intelligent hydraulic adjustment system.

Matching Screening and Cleaning Device

Vibrating screening equipment

Vibrating screening equipment

Function: Closed-circuit screening (e.g. circular vibrating screen) returns substandard particles to the crusher, forming a circular crushing process to ensure that the final particle size is qualified.

Technical parameters: screen hole size decreases step by step (e.g. >5mm after coarse crushing, 0.5-1mm after fine crushing).

Cleaning device

Design Points: Install removable cleaning nozzle on the side wall of the screening device, together with the water tank at the bottom, to reduce the dust pollution and separate the impurities.

Applicable scenario: high humidity ores or manganese ores containing more clay to avoid clogging the equipment.

Process optimisation suggestions

Tertiary Crushing + Closed Circuit Screening Process

Steps: Jaw crusher (coarse crushing) → Cone crusher (medium crushing) → Hydraulic Double Roller Crusher (fine crushing) → Vibratory screening → Unsatisfied particles return to re-crushing.

Advantage: Graduated crushing reduces the pulverisation rate (e.g. controlling the particle size below 10mm ≤10%) and improves the quality of subsequent smelting.