Tin ore is an important material for the production of tin and tin metal. Tin and tin alloys are important materials used in modern defence, modern industry, and cutting-edge science and technology. From tin ore to tin metal and tin alloy, it needs to go through a series of production process. HSM Heavy Industry shares the crushing process in tin ore plus crushing process, as well as the crusher and crushing production line used in tin ore crushing!

Tin ore crushing process design

Tin ore crushing equipment are: jaw crusher (coarse crushing) → impact crusher (medium crushing) → roll crusher (fine crushing)

Selection of crushing sections

Two-stage crushing: suitable for most of the tin ore (such as medium hardness, uniform particle size distribution), using a combination of coarse + fine crushing.

Three-stage crushing: for high hardness or oversize ore (e.g. raw ore size >600mm), increase the middle crushing link.

Closed loop: through the vibrating screen (such as circular vibrating screen) to achieve the return of substandard materials to re-crushing, to ensure that the final particle size up to standard.

Crushing Plant Configuration Programme

Rough crushing section:

Jaw crusher

Jaw crusher: recommended models such as PE600×900 (capacity 50-100t/h) or PEW860 European jaw crusher (capacity 250t/h), suitable for ores with compressive strength ≤ 320MPa, with large crushing ratio and simple structure.

Middle/fine crushing section:

Impact crusher

Impact crusher: suitable for medium-hard and soft ores, with shaping function and better particle size.

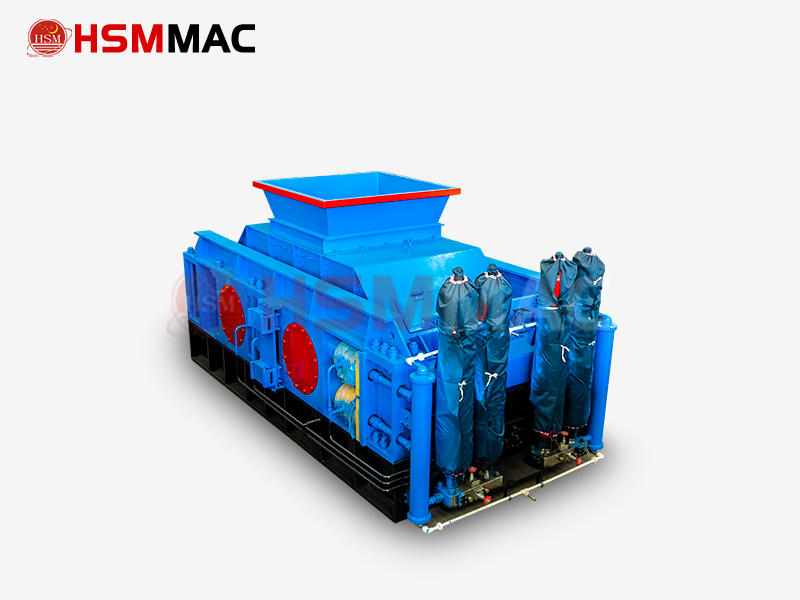

Roll Crusher

Roll Crusher: High efficiency crushing through high pressure roll extrusion, especially suitable for high hardness ores, can reduce dust generation.

Key Equipment Technical Parameters Control

Particle size control

The target size (usually ≤12mm) is achieved by adjusting the crusher discharge and screening equipment (e.g. 15mm screen). Intelligent sensors are used to monitor the crushing ratio and product size in real time, and dynamically adjust the feeding speed and rotational speed.

Optimisation of wear resistance of crushing equipment

The crushing equipment uses wear-resistant materials such as high chromium alloy and titanium nitride to manufacture wear parts (e.g. jaw plates and liners) to prolong service life. Optimise the structural design of the equipment (e.g. impact crusher cavity type, cone crusher laminated crushing) to reduce the wear area.