river pebbles

Engineers design the pebble crusher to boost the capacity and efficiency of mineral grinding circuits—especially those using SAG (Semi-Autogenous Grinding) mills. It solves a key bottleneck in grinding operations. It processes the coarse, hard “pebbles” that SAG mills discharge but cannot grind efficiently. Instead of letting this valuable, energy-rich ore recirculate nonstop, the pebble crusher reduces its size. This lets downstream ball mills process the material effectively.

For this tough task, the roller crusher emerges as a highly effective, reliable solution. Its strong, compressive crushing action handles hard, abrasive quartz or granite pebbles with consistent, continuous reduction. The roller crusher uses a slow-speed, high-pressure mechanism. This design cuts down on excessive, problematic fines and creates a consistent, granular product—ideal feed for ball mills. This precise control over product size delivers multiple benefits. It creates a more stable grinding environment, boosts overall circuit throughput, and cuts energy use per ton of ore processed. Integrate a durable roller crusher as your dedicated pebble crusher. It’s a strategic investment that unlocks your plant’s hidden capacity.

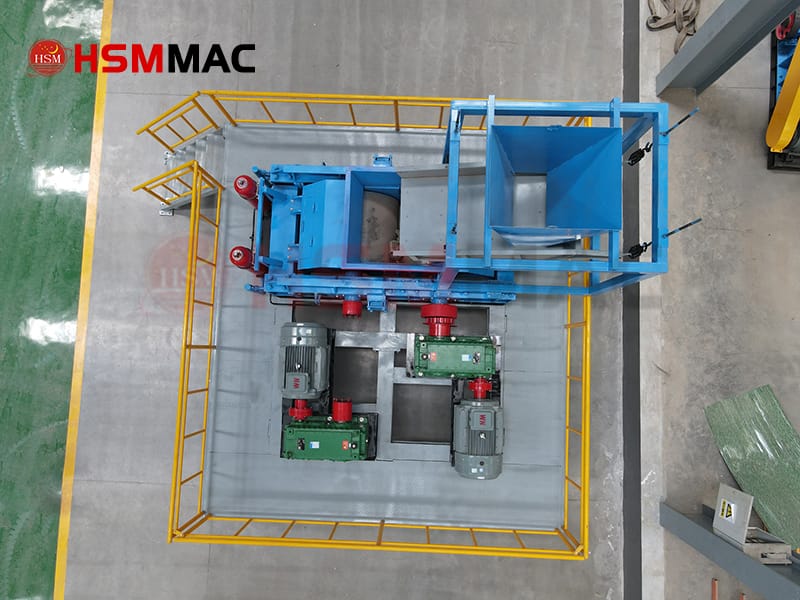

Pebble Crusher

Ready to remove bottlenecks from your grinding circuit? Discover how we engineer our heavy-duty roller crushers to excel as high-performance pebble crushers.