Roll Crusher Application Scope

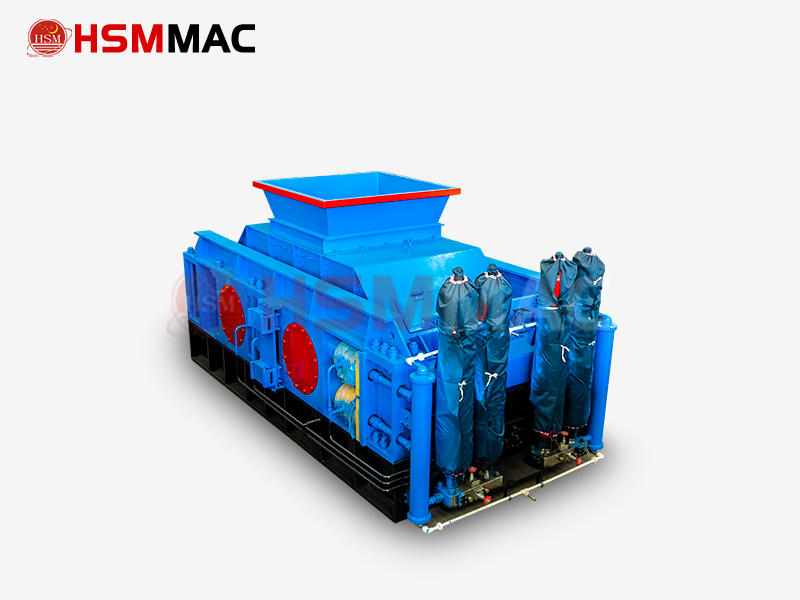

Roll Crusher (alias: Double Roll Crusher, Roll Crusher) is a compact, reliable, cost-effective crushing equipment used in many industrial fields. A roll crusher squeezes material with two rotating rollers, which are either smooth (for hard materials) or toothed (for brittle materials). The following are the main applications and scenarios of roll crusher:

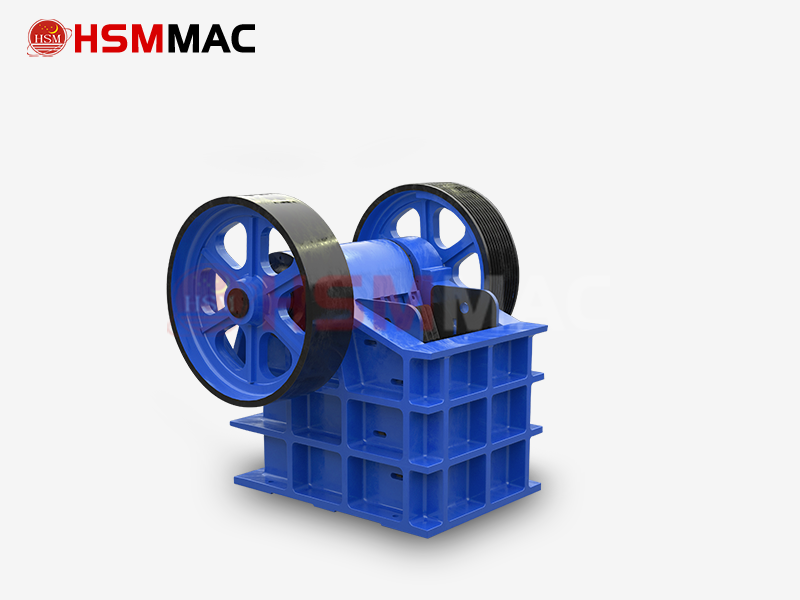

Roll Crusher

1.Industry Application Scope

Coal industry

Direct crushing of raw coal: No need to remove gangue in advance, only need to remove iron, remove impurities can be crushed, simplify the coal selection process, reduce investment costs.

Advantage: uniform particle size of the crushed material, low over-crushing rate, suitable for large coal mines or coal processing plants.

Mining and metallurgy industry

Ore crushing: fine crushing of iron ore, quartzite and other minerals of medium hardness (compressive strength ≤ 160MPa).

Refractory and building materials: processing cement raw materials, limestone, refractory clay, etc., for coarse and medium crushing process.

Building materials and environmental protection

Artificial sand production: Making sand from pebbles, construction waste and other stones, with a finished size of 50μm-20mm.

Ceramic industry: crushing kaolin and other raw materials to meet the requirements of fine crushing.

Chemical and Power Industry

Chemical raw material processing: such as crushing fertiliser raw materials, mineral additives and other brittle materials.

Fuel preparation: used in coal pre-treatment of coal-fired power plants to improve combustion efficiency.

2.Applicable Material Characteristics

Material type: brittle lumpy materials (such as coal, ore) or clayey materials (such as clay).

Hardness requirements: compressive strength ≤ 160MPa, too hard materials need to be matched with hydraulic or spring overload protection device.

Special scenes:

Smooth roller surface: suitable for hard materials (such as quartz stone).

Grooved roller surface: designed for brittle materials (such as raw coal, coke), can be configured with single, double or triple roller structure.

3. Particle size processing capacity

Feed size: ≤80mm.

Discharge size: can be controlled between 50μm-20mm by adjusting the roll spacing to meet the demand for fine crushing.

Capacity enhancement: when used in the grinding system, it can increase the output by 30%-40% and reduce the total energy consumption by 20%-30%.

4. Precautions for the use of roller crusher

Iron removal and damage prevention: Iron removal device must be installed to avoid metal debris damaging the roller surface.

Clogging treatment: sticky material clogging, stopping the machine to clean up, it is strictly prohibited to poke the mine in operation.

Maintenance requirements: regular inspection of the roller surface wear, timely adjustment of the discharge port or replacement of the roller skin (mostly made of high manganese steel).

Safety protection: large materials may fly out, need to install protective cover; transmission parts need to be lubricated regularly.

5.Application cases of roller crusher

Construction waste regeneration: waste concrete is crushed into aggregate, which is used for road base filling or recycled building materials.

Ultra-fine crushing in mining industry: High-pressure roller mill derived model can crush materials ultra-fine, energy-saving and low steel consumption.

Roll crushers have become the core equipment for medium and fine crushing operations with their flexible discharge adjustment, low overcrushing rate and high processing efficiency. Specific models (e.g. 2PG, PCM series) need to be selected according to material characteristics and capacity requirements. For further technical parameters (e.g. motor power, weight), please refer to the relevant industry standards or manufacturer’s literature.