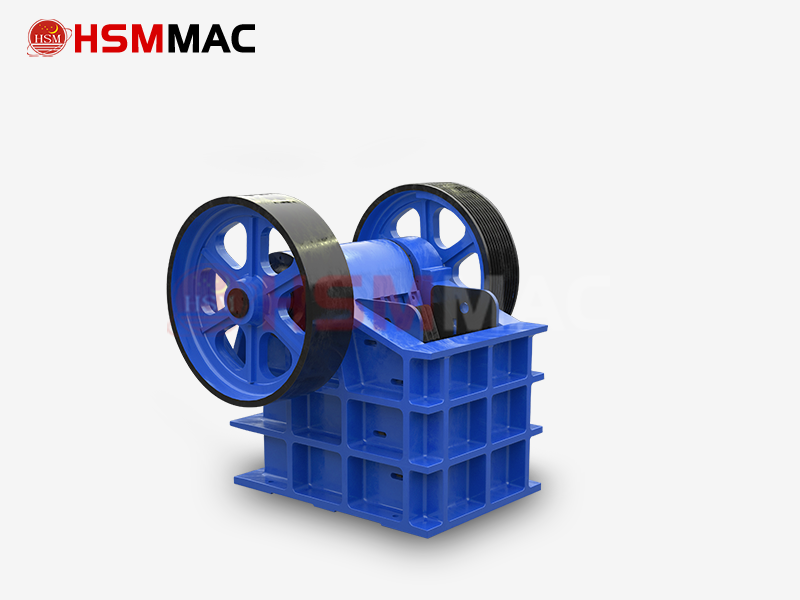

In modern industry, the double tooth roller crusher serves as an efficient crushing device widely applied in mining. Construction materials, chemical industries, and more. It achieves material crushing through the squeezing and shearing actions of two counter-rotating toothed rolls.

Design Advantages of the Double Tooth Roller Crusher

The ingenious design feature of this equipment lies in its adjustable toothed roll spacing. Which allows operators to adjust the degree of crushing according to different material characteristics and production requirements. Thereby achieving the desired particle size distribution. Moreover, the robust and durable structural design ensures long-term stable operation, reducing maintenance costs.

Suitable for materials of various hardness levels, from softer coal to hard rock, the double tooth roller crusher not only enhances production efficiency but also reduces dust generation, contributing positively to environmental protection. In terms of energy conservation, compared with traditional crushing methods, the double tooth roller crusher consumes less energy, aligning more closely with the concept of green production.

With the development of technology, manufacturers continuously optimize and improve the equipment, making it smarter. For instance, automatic monitoring systems can real-time monitor the condition of the equipment, promptly warn of faults, ensuring safe and efficient production. In summary, with its unique advantages, this equipment has become an indispensable important asset in many industries.