How to Process Basaltic Rocks Efficiently? Pair Sand Making Machine with Roller Crusher!

When processing hard, abrasive basaltic rock into high-quality construction sand, efficiency and equipment longevity hinge on smart process design — and the roller crusher is a core component of this optimized setup. Pairing your sand making machine with this robust pre-processing tool creates a two-stage system that balances yield, cost control, and operational durability.

Why Pre-Processing Matters for Basalt

For abrasive materials like basalt, a dedicated preliminary crushing step is non-negotiable. This is where a heavy-duty crushing unit (such as the roller crusher) adds value: after primary crushing, raw basalt is fed into it, and controlled compression reduces the material to a uniform intermediate size. This eliminates oversized, jagged fragments that would otherwise overload and wear down the sand making machine.

By delivering a consistent, optimally sized feedstock, this pre-processing tool lets the sand maker focus on its strength — shaping fine, graded sand — rather than expending energy on initial breaking. This division of labor cuts wear on the sand maker’s high-cost components, lowers overall energy use, and boosts the entire line’s throughput by up to 30% in typical basalt processing scenarios.

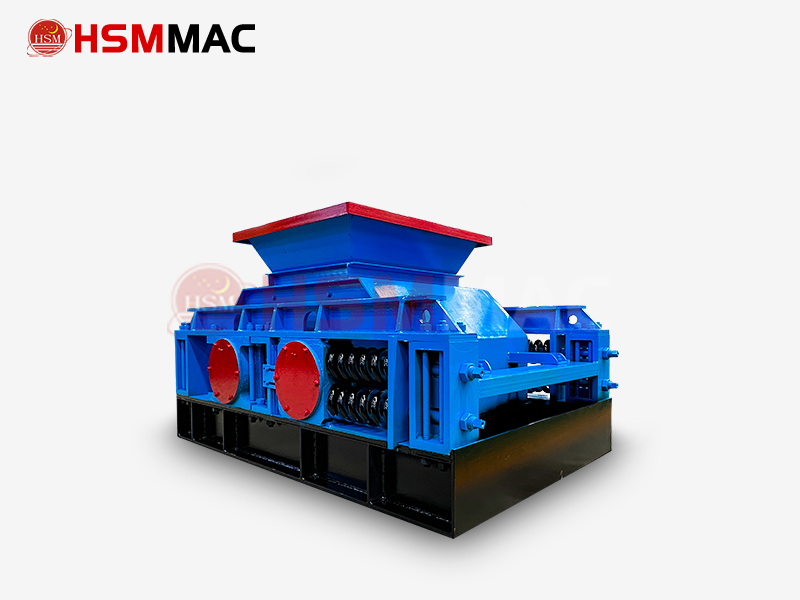

hydraulic roller crusher

Long-Term Benefits of the Two-Stage Setup

Integrating a roller crusher also extends your plant’s operational lifespan. Its steady, low-impact crushing action minimizes material fatigue in downstream equipment, while its durable build handles basalt’s abrasiveness with far less maintenance than alternative pre-processing options. For example, plants using this pairing report 20% fewer unplanned shutdowns related to wear parts compared to setups without this dedicated pre-processing stage.

This system isn’t just about immediate efficiency — it’s about building a sustainable, high-yield operation. Whether you’re processing small batches or scaling to large production volumes, the right pre-processing tool paired with your sand maker ensures consistent sand quality and lower long-term operational costs.

the workshop

Ready to build a more efficient, durable basalt processing system? Our experts will help you select the ideal roller crusher model to match your sand making machine, tailoring the setup to your production volume and sand quality requirements.