Basalt, known for its high density and abrasiveness, presents a unique challenge for crushing equipment. For this demanding application, the roller crusher has become a preferred choice due to its specific design strengths that match the material’s characteristics.

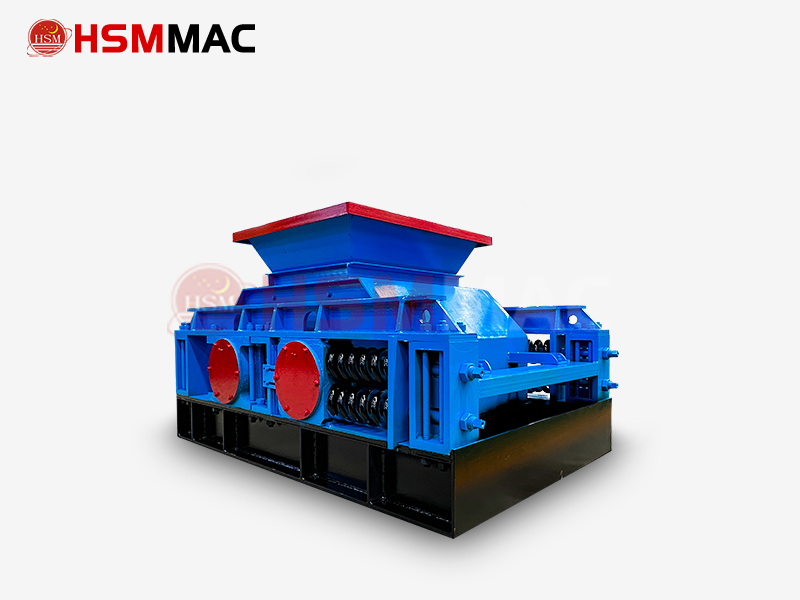

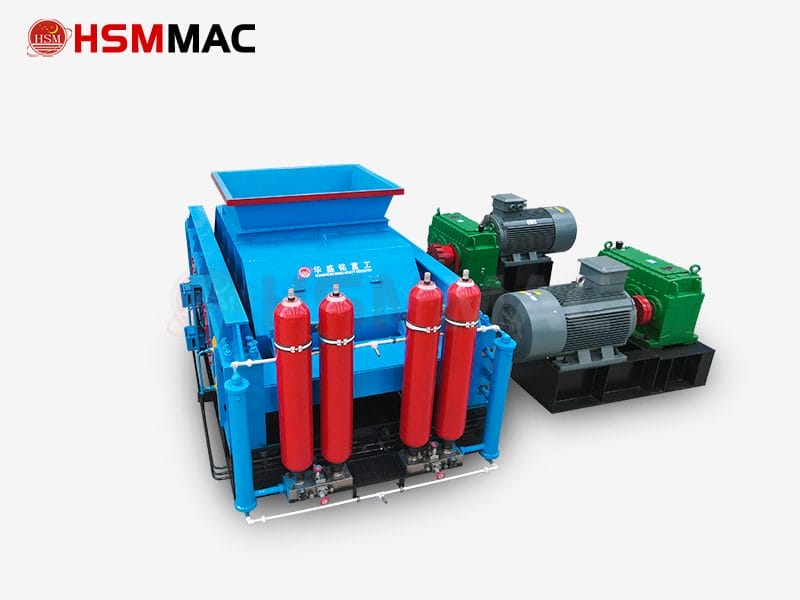

roller crusher

The roller crusher excels in processing basalt because of its durable, compression-based crushing principle. Unlike high-impact methods that can accelerate wear on components, the machine’s slow-speed, high-pressure rollers are built to withstand continuous abrasion. They fracture the tough rock along natural cleavage lines, efficiently reducing it without excessive wear. This results in a more consistent product size and extended service life for wear parts.

Additionally, this machine delivers the precise product control necessary for premium basalt aggregates. It produces the well-graded, cubical material required for high-friction applications like railway ballast and asphalt. Its mechanical stability under heavy loads ensures continuous operation, maximizing throughput from one of the hardest natural stones. For quarries prioritizing durability, product quality, and uptime when processing basalt, this technology offers a reliable and optimal solution.

Roller Crusher

Processing hard, abrasive rock? Learn why our heavy-duty roller crusher is the engineered solution for efficient basalt reduction.