The double-toothed roll crusher is a crushing device operating on the principles of extrusion and shearing. Its core structure consists of two counter-rotating toothed rolls. Widely applied in coal, mining, building materials and other industries. It is specially designed for the primary and secondary crushing of materials with medium hardness or below. The wear-resistant teeth distributed on the surface of the rolls can be customized according to material characteristics. Through the relative rotation of the toothed rolls, materials entering the crushing chamber are firmly gripped. Then crushed by extrusion and shearing, resulting in uniformly sized crushed products with minimal over-crushing. Double-Toothed Roll Crusher: A Powerful Tool for Crushing Operations Compared with traditional crushers, it boasts distinct advantages: compact structure, small floor space, and easy installation and maintenance; stable operation, low energy consumption, and high production efficiency; strong adaptability with no easy clogging when handling viscous materials. In the coal industry, it can crush raw coal to ensure the smooth progress of subsequent separation processes. In the mining sector, it is capable of processing materials such as limestone and shale, providing qualified aggregates for subsequent production procedures. With technological upgrades, the new-type double-toothed roll crusher is equipped with an intelligent control…

Roll crushers (especially double roll type) are favored in mining, construction and infrastructure projects for unique advantages. Henan Huashengming Heavy Industry, a professional manufacturer, integrates advanced tech into its roll crushers, standing out globally. Below are their core advantages. Why Huashengming Crushers Stand Out in the Global Market In the competitive crushing equipment industry, Huashengming Heavy Industry has established a solid reputation by focusing on technological innovation, product quality, and customer-centric services. Here are the core advantages that make its crushers a top choice for customers worldwide: 1. Patented Wear-Resistant Technology for Long-Term Stability One of the biggest pain points in crusher operation is frequent replacement of wearing parts, which increases maintenance costs and downtime. Huashengming addresses this issue with its patented high-chromium manganese steel roller skin added with rare metals. This special material ensures that the wearing parts do not need to be replaced within 1 to 2 years, significantly reducing maintenance frequency and operational costs. The company has also obtained national patents for its roller design and precise discharge particle size adjustment technology, guaranteeing stable and consistent crushing results. 2. Energy-Saving & Eco-Friendly With simple structure, they save 20-50% energy vs impact/cone crushers. Advanced sealing prevents dust leakage;…

The working principle of a roll crusher centers on controlled compression between two counter-rotating rolls, delivering several distinct operational benefits. As materials pass through the adjustable gap between the rolls, they undergo gradual size reduction rather than sudden impact, resulting in superior product quality and system efficiency. Operational Advantages Through Design: Controlled Compression – Gradual crushing minimizes fines production Adjustable Gap System – Precise control over final product size Even Wear Distribution – Prolongs equipment service life Energy Efficient Operation – Lower power consumption per ton processed Versatile Material Handling – Effective for both dry and slightly moist materials This efficient working mechanism makes roll crushers particularly valuable in mineral processing, aggregate production, and industrial applications where product consistency matters. Ready to optimize your crushing process? Contact Huashengming Heavy Industry in Zhengzhou to explore how our roll crushers can improve your operational efficiency and product quality.

In mining, construction and aggregate processing, choosing crushing equipment impacts efficiency, costs and quality directly. Among options, roll crushers are reliable and efficient, with unique advantages making them essential in various industrial settings. Let’s explore their key benefits. 1. Excellent Crushing Effect with Uniform Particle Size One of the most prominent advantages of roll crushers is their ability to produce uniformly sized particles. Unlike some other crushing equipment that may generate irregularly shaped or overly fine materials (powder), roll crushers operate through the extrusion and rolling of two parallel rolls. The gap between the rolls can be precisely adjusted according to production needs, ensuring that the crushed materials meet the required particle size standards. This uniform particle size is particularly crucial for subsequent processing links, such as grinding or screening, as it improves the efficiency of follow-up operations and enhances the quality of final products. 2. Low Energy Consumption and High Energy Efficiency In today’s industrial production, energy conservation and emission reduction are core goals for enterprises. Roll crushers excel in energy efficiency compared to many traditional crushers. The crushing principle of roll crushers (extrusion and rolling) requires less energy input to break materials compared to impact crushing or hammer…

Double roll crushers and hammer crushers are widely used in crushing applications like mineral processing and construction waste recycling. However, their structural and working principle differences lead to distinct application scenarios and performance. Below is an overview of their key differences to guide equipment selection. 1. Working Principle: Compression Crushing vs Impact Crushing The core difference between the two lies in their working principles, directly influencing their crushing methods and material adaptability. Double roll crushers use compression crushing. Equipped with two parallel rotating rolls, they squeeze materials entering the roll gap until reaching the required size. The process is gentle, relying on static pressure. Hammer crushers adopt impact crushing. A high-speed rotating rotor with hammer heads strikes incoming materials, breaking them into small pieces. Secondary crushing occurs via collisions with the chamber lining and other materials, with discharge through a bottom sieve plate. 2. Applicable Materials: Soft/Hardness and Brittleness/Ductility Their crushing principles result in obvious differences in material adaptability. Double roll crushers suitmedium-soft, ductile materials (e.g., coal, limestone, gypsum). They are unsuitable for hard brittle materials (causing roll wear/jamming) but excel with high-moisture materials (less adhesion/blockage). Hammer crushers are ideal for medium-hard brittle materials (e.g., limestone, dolomite, shale). They perform…

In the dynamic mining and construction machinery sector, choosing a reliable stone crusher manufacturer is key to project efficiency and profitability. Henan Huashengming Heavy Industry Machinery Co., Ltd., a high-tech enterprise based in Gongyi, Zhengzhou, has become an industry benchmark with a focus on innovation, quality and customer-centric solutions. For over a decade, we’ve delivered premium crushing equipment and full-range services to global clients. Our Core Strength: Technology-Driven Differentiation Unlike many “one-size-fits-all” manufacturers, Huashengming excels in the niche of mining crushing & screening equipment. Our core strength lies in 20+ national patents, including the pioneering “centrifugal high-chromium manganese steel roller skin” and latest “centrifugal composite roller skin” for double roller crushers. Crafted via a unique casting process with rare metal formulas, this roller skin has a hardness above HRC62 and a service life of 2-3 years—2-3 times that of ordinary equipment. Aligning with global intelligent and green production trends, we’ve integrated industrial internet control systems into all equipment. Our crushers support real-time gap adjustment (1-20mm stepless), pressure monitoring and mobile fault self-diagnosis. AI-driven parameter optimization cuts energy use by 30% vs. traditional models, enabling unmanned, high-efficiency operations. We also hold EU CE environmental certification, with noise levels below 75dB thanks…

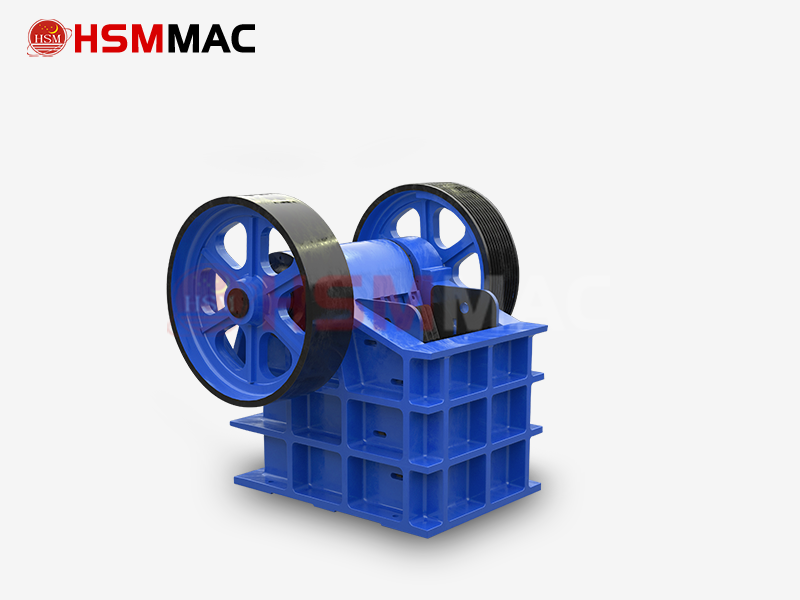

Efficient raw coal crushing is a vital first step in coal mining and processing. Among various crushing equipment, jaw crushers have long been irreplaceable due to their stable performance, strong adaptability, and simple structure. Let’s take a concise look at this “workhorse” for coal crushing. 1. What Is a Jaw Crusher & Its Working Principle for Coal? Jaw crushers crush materials by the periodic movement of the movable jaw plate relative to the fixed one. For coal crushing, their working process is simple yet efficient. Raw coal (including large irregular lumps) is fed into the V-shaped crushing cavity (formed by fixed and movable jaw plates). Driven by the eccentric shaft, the movable jaw swings reciprocally: it squeezes coal when moving toward the fixed jaw, and qualified crushed coal falls from the discharge port by gravity when swinging away. Unqualified lumps stay for re-crushing. A key advantage is their ability to handle large raw coal (up to several hundred millimeters), avoiding equipment blockage caused by oversized materials. 2. Why Jaw Crushers Are First-Choice for Coal Crushing? There are various coal crushing equipment (e.g., cone crushers, impact crushers), but jaw crushers are preferred for primary coal crushing for the following reasons:…

Roller Crushers provide an efficient secondary crushing stage in construction waste sand making machine plants, offering key benefits for processing recycled materials. Core Advantages: 1.Precise Size Control: The adjustable roller gap finely calibrates output (0-10mm) to produce specific sand grades required by your construction waste sand making machine. 2.Low-Noise & Low-Dust Operation: Compression crushing is inherently cleaner and quieter, supporting compliance in sensitive environments. 3.Low Maintenance & Cost: Simple design and long-lasting wear parts reduce downtime and operational expenses. 4.Handles Sticky Materials: Effectively processes moist, adhesive waste (e.g., wet concrete) with minimal clogging risk. 5.Compact & Flexible: A small footprint allows easy integration into both new and existing construction waste sand making machine lines. Upgrade your recycling plant’s efficiency and product quality. Contact Huashengming to learn how our Roller Crushers can optimize your construction waste sand making machine system.

With its unique dual-rotor crushing structure, the double-stage crusher boasts strong compatibility for various materials and is widely applied in mining, construction, chemical engineering and other fields. For brittle materials such as coal and gangue, it adopts a low-speed and high-torque design. Enabling one-time crushing to a particle size below 30mm. The crushing process causes no over-crushing, effectively improving material utilization rate. Moreover, the crushing chamber is not prone to blockage, and the processing efficiency is increased by more than 30% compared with traditional equipment. Double-Stage Crusher: Efficient Crushing Solution for Diverse Materials For medium-hard ores like limestone and dolomite, the double-stage crusher achieves precise control of discharge granularity through the synergistic effect of two-stage extrusion and impact, meeting different requirements of aggregate production. Meanwhile, the wear-resistant liner material enhances equipment wear resistance and extends service life. When processing construction waste, concrete blocks and other materials, its sealed crushing design reduces dust pollution. The crushed recycled aggregates meet the standards of construction sand, facilitating resource recycling. In addition, this equipment has good adaptability to wet materials. For high-moisture materials including clay and shale, the optimized crushing chamber structure prevents material adhesion and blockage, ensuring production continuity. With its multi-material adaptability….

Impact crushers are widely used in mining, building materials and other fields due to their high-efficiency crushing performance. Different types of impact crushers have distinct focuses on material adaptability. And precise matching can improve crushing efficiency and finished product quality. Impact Crusher: Type Classification and Material Crushing Adaptation Solutions The 反击式 impact crusher excels at processing medium-soft hardness materials, such as limestone, dolomite, shale, etc. These materials have high brittleness and compressive strength below 300MPa. During crushing, repeated crushing is formed through the impact of hammers and the rebound of impact plates. The finished products feature uniform particle shape and low content of needle-like and flaky particles. Making them suitable for highway subbase and concrete aggregate production. The vertical shaft impact crusher (sand making machine) focuses on the fine crushing and shaping of medium-hard and above hardness materials, such as granite, basalt, river pebbles, etc. Materials are accelerated by the high-speed rotating impeller and then impact the crushing cavity, integrating both crushing and shaping functions. The finished products are cubic in shape, which are applicable to scenarios with strict requirements on particle shape, such as high-speed railways and manufactured sand production. During selection, precise matching should be carried out according…

In brick-to-sand recycling systems, the Impact Crusher and Jaw Crusher each play indispensable roles. The Jaw Crusher serves as the core of primary crushing, responsible for the initial size reduction of large brick and concrete blocks. The Impact Crusher acts as the key secondary crushing equipment, further optimizing material shape to provide ideal feed for the Bricks Sand Making Machine. Core Functions of the Jaw Crusher: Primary Reduction: Processes large construction debris and whole bricks with high crushing strength, accepting feed sizes up to 500mm. Stable Feed Supply: Provides consistent and uniform material for subsequent stages, including the Impact Crusher and the Bricks Sand Making Machine. Pre-Screening Function: Provides preliminary separation of impurities like rebar and wood from brick material. Core Functions of the Impact Crusher: Particle Shape Optimization: Utilizes impact crushing to produce more cubical particles, enhancing final sand quality. Fine Crushing: Further reduces material from the Jaw Crusher to the optimal feed size for the Bricks Sand Making Machine. High Adaptability: Capable of processing bricks with some moisture content, reducing clogging risks. System Synergy Advantages: Increased Throughput: Two-stage crushing can boost overall system capacity by 40-60%. Optimized Energy Consumption: Clear division of labor reduces specific energy consumption by 25-35%. Quality Assurance:…

In mineral processing, building materials and metallurgy, crushing equipment is crucial. The high-pressure roller crusher (HPRC) has become a game-changer in the industry due to its unique working principle and outstanding performance. Let’s take a concise look at this innovative equipment. What Exactly Is a High-Pressure Roller Crusher? As an energy-saving and efficient crushing device for fine and ultra-fine crushing, HPRC crushes materials via high pressure between two counter-rotating rollers (one fixed, one movable). Its core components include roller bodies, hydraulic system, transmission system and feeding/discharging devices, with wear-resistant roller surfaces ensuring long service life even for hard materials. Core Advantages That Make It Stand Out Compared with traditional crushers (jaw, cone, impact crushers), HPRC has distinct advantages, making it a top choice for enterprises upgrading production lines: 1. Exceptional Energy Efficiency It boasts exceptional energy efficiency. By adopting the inter-particle crushing principle, HPRC converts over 80% of input energy into effective work, far outperforming traditional crushers with high energy waste. 2. Superior Product Quality Its products feature uniform particle size and high fine-particle content, with regular shapes. This greatly improves subsequent processing efficiency and quality for industries with strict particle size requirements. 3. High Crushing Efficiency and Large Handling…

+86-18703839693

+86-18703839693