—— Preferred Fine Crushing Equipment for Cement Processes In the Cement Sand Making Machine workflow (Jaw/Impact Crusher → Roller Crusher → Ball Mill), the Roller Crusher is a key component. Notably, its unique design and technology boost production efficiency and product quality. Its core advantages are as follows: 1. Superior Particle Shape for Cement Needs Through extrusion crushing, it produces regular cubic particles: uniform gradation, low flaky/needle-like content. Thus, it meets cement aggregate strength needs without extra shaping. 2. Lower Energy Consumption, Controllable Costs Its energy-efficient design cuts unit energy use vs. other fine crushers. Additionally, low over-crushing reduces material waste and grinding load—slashing long-term costs. 3. Strong Adaptability, Seamless Process Connection It flexibly fits Cement Sand Making Machine lines of all capacities. Specifically, it refines intermediate-crushed materials precisely, with output size matching Ball Mill grinding. 4. Simple Operation, Convenient Maintenance It has a compact, small-footprint structure; installation is flexible. Also, wearing parts are easy to replace, and daily maintenance is minimal—so downtime drops, keeping production continuous. Hua Shengming Heavy Industry’s Roller Crusher works well with Cement Sand Making Machine setups. With stable performance and high cost-effectiveness, it helps enterprises cut costs and boost efficiency. For customized solutions, contact us now!

In blue quartz sand making projects, the performance of blue quartz sand making machine is critical to production efficiency and product quality. The Roller Crusher, engineered to match blue quartz’s characteristics, addresses key challenges such as high equipment wear and uneven particle size. Below are its core advantages: 1.Exceptional Wear Resistance Blue quartz’s high hardness accelerates wear on conventional equipment. The Roller Crusher adopts high-strength wear-resistant alloy rollers and an extrusion-based crushing principle, avoiding impact-induced damage. It maintains stable long-term operation and reduces vulnerable part replacement frequency. 2.Superior Finished Product Quality Dual counter-rotating rollers ensure uniform material stress, minimizing over-crushing. The finished sand features regular cuboidal particles with low fine powder content, meeting stringent requirements for high-end building materials and precision casting. 3.Flexible Particle Size Adjustment Equipped with a convenient roller gap adjustment mechanism (mechanical or hydraulic), the crusher precisely controls discharge size without replacing core components, adapting to both coarse and fine sand demands for customized production. 4.Easy Maintenance & Compact Design Its streamlined structure saves space and enables seamless integration into existing production lines. Vulnerable parts like wear-resistant liners are easy to disassemble and replace, reducing maintenance downtime and operational costs. 5.Eco-Friendly Operation A closed housing prevents dust…

As a key equipment in the crushing field. The double-stage crusher has become the preferred choice for industries such as construction materials, mining, and chemical engineering. Thanks to its unique dual-cavity crushing structure. Its core design breaks through the limitations of traditional single-stage crushing: through the coordinated operation of two-stage rotors, it achieves gradual refined crushing of materials, significantly improving crushing efficiency and finished product quality. Double-Stage Crusher: Core Equipment for High-Efficiency Crushing During operation, materials enter the primary crushing cavity through the feed inlet and are crushed by the high-speed rotating rotor hammers. The initially crushed materials then fall into the secondary crushing cavity. Where deep crushing is completed through secondary extrusion and impact. ultimately forming finished products with uniform particle size. This double-stage crushing mode effectively avoids material clogging issues, with a crushing ratio of 10-20, capable of directly crushing large materials to below 3-5 millimeters, meeting the processing needs of various industries. Compared with traditional crushers. The double-stage crusher offers distinct advantages: adopting wear-resistant alloy hammers and thickened liners. Its service life is extended by over 30%. The sealed design reduces dust pollution, complying with environmental protection standards; it features a compact structure with a small footprint,…

In material processing, efficiency, precision, and durability are critical. Four-roll crushers stand out for medium-to-fine crushing, delivering consistent results across mining, construction, cement production, and recycling. Here’s why they’re a top choice for modern lines. Core Advantages Dual-Stage Crushing Two roll pairs (primary + secondary) eliminate multi-stage crushing. Achieve high reduction ratios (up to 1:20) and uniform particle sizes with precise control. Energy-Efficient Performance Advanced drives and optimized rolls cut energy use by 20-30% vs. traditional crushers. Handle 5-500 tons/hour with synchronized rotation and adjustable gaps. Durable & Low-Maintenance Wear-resistant manganese/alloy steel rolls and heavy-duty frames withstand hard/abrasive materials (granite, ore, coal). Minimal moving parts + quick-change roll sleeves reduce downtime. Industry Versatility Process soft-to-hard, wet-to-dry materials: Mining: Ore & coal crushing Construction: Concrete/asphalt recycling Cement/Aggregates: Fine aggregate production Chemical/Fertilizer: Limestone/gypsum processing How It Works (4 Simple Steps) Feed: Raw materials enter via a hopper (vibrating feeder for uniformity). Primary Crush: First roll pair (serrated/smooth) reduces large materials. Secondary Crush: Second pair (tighter gap/higher speed) refines to target size. Discharge: Ready-to-use final product exits the crusher. Key Selection Tips Material Properties: Match roll type (serrated/smooth) to hardness/moisture/feed size. Output Needs: Adjust gaps/speed for desired particle distribution. Capacity: Align with production…

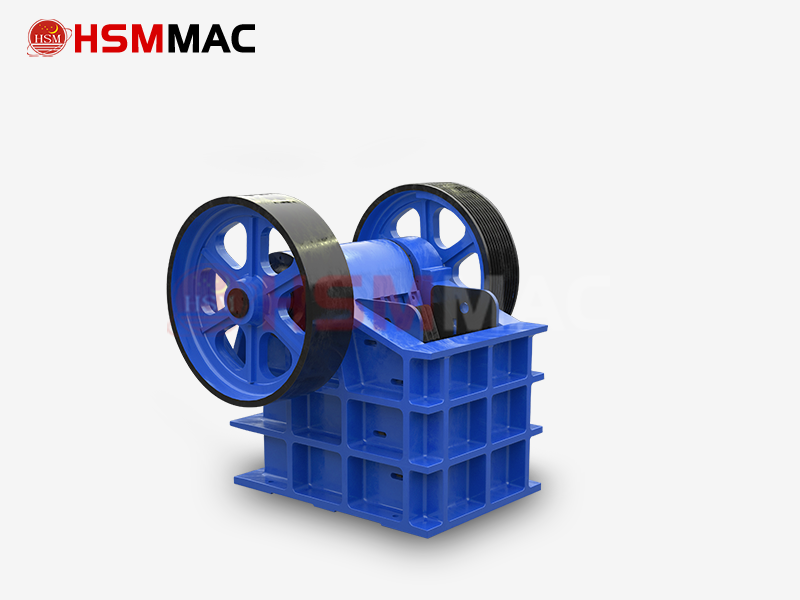

In the aggregate for building construction sand making machine line, primary crushing defines later efficiency and quality. For bulk raw materials (e.g., granite, construction waste), HSM Jaw Crusher is the core primary crusher: it’s wear-resistant, efficient, and adaptable, enabling smooth aggregate/sand production. Core Advantages Powerful Crushing Using fixed + movable jaw extrusion, it handles large raw materials with a deep V-chamber. It works on hard/soft rocks and waste, producing crushed output that fits downstream equipment. Stable & Versatile With flexible capacity options, it suits small mixing stations to large mines. Its rigid, low-vibration design supports 24/7 operation. Durable & Low-Maintenance Wear parts last longer than standard models. Its simple structure lets non-professionals handle quick routine checks. Seamless Line Integration Protects downstream gear by pre-crushing bulk materials. Boosts product quality with uniform output, cutting extra screening costs. Flexible setup (fixed/mobile) works for on-site tasks like waste recycling. HSM Jaw Crusher is tailored for aggregate for building construction sand making machine systems. We offer custom solutions—contact us for a quote!

As a standout basalt sand making machine, the Roller Crusher excels in processing high-hardness basalt (Mohs hardness 6-7). It directly addresses traditional sand-making pain points like low efficiency, poor particle shape and high costs, making it the top choice for basalt sand production lines. Below are its core advantages: 1. Strong Wear Resistance: Built for Basalt’s Hardness This basalt sand making machine adopts HRC60+ high-chromium alloy or wear-resistant welded roller surfaces, tailored for basalt’s wear resistance. The roller replacement cycle reaches 1 year (30% longer than ordinary equipment). Its “double-roller extrusion + shear” principle avoids violent material impact, reducing vulnerable part wear and solving frequent replacement issues of traditional machines. 2. High-Quality Sand: Meets High-End Demands Extrusion crushing avoids over-crushing, producing sand with ≥90% cube particles and ≤5% powder content—fully meeting high-end requirements for concrete aggregates and road bases. With 0-50mm stepless adjustable discharge size, it flexibly produces coarse, medium and fine sand, a key edge of this basalt sand making machine. 3. Energy-Saving & Cost-Effective: Lighten Operational Burden Compared with other basalt sand making machines, it has ultra-low unit energy consumption (5-8kWh/ton), saving 25% more energy than Jaw Crushers and 18% than Impact Crushers. Its compact structure takes only…

The impact crusher is a crucial piece of equipment in the mining and building materials sectors, with its core crushing function stemming from the synergistic effect of high-speed impact and collision. After entering the crushing chamber, materials are propelled towards the impact plate or lining plate by the high-speed rotating rotor, resulting in intense impact and rebound. During this process, stress concentration within the materials induces cracks that rapidly propagate, ultimately causing the materials to fracture along weak planes and achieve efficient crushing. Impact Crusher: The Core Force for Efficient Crushing Its crushing mechanism involves two main actions: First, the kinetic energy impact directly imparted to the materials by the rotor, which enables the materials to acquire sufficient crushing energy through high-speed projection; second, the mutual collisions and friction among materials, which result in secondary crushing and further refine the particle size. This composite action mode of “impact + collision” allows the equipment to maintain high crushing efficiency and low energy consumption when handling hard materials such as granite and basalt. Compared to traditional compression-type crushers. The impact crusher significantly enhances the uniformity of the finished particle shape through its dynamic crushing process, reducing the content of needle-like and flaky…

For lithium ore crushing operations, selecting a double-roll crusher (lithium stone crusher) is a highly viable option, particularly when you have stringent requirements for product purity, particle size control, and production efficiency. With its unique operating principle, it excels in ensuring product purity and precisely controlling particle size. 1. Working Principle The double-roll crusher primarily crushes materials by squeezing and grinding them between two counter-rotating rolls. When lithium ore enters the crushing chamber through the top feed opening between the rolls, it undergoes high-pressure compression and shear forces to achieve fragmentation. This relatively “gentle” crushing method offers significant advantages in lithium battery material processing: 2. Advantages Eliminates Metal Contamination, Ensures High Purity of Battery Materials This represents the core advantage of double-roll crushers in processing lithium ore. Lithium battery cathode materials impose extremely stringent requirements on metal impurities such as iron (Fe) and chromium (Cr). Traditional crushers using metal rollers like manganese steel inevitably introduce trace metal contamination. Double-roll crushers, however, can employ ceramic or zirconia rollers, ensuring no metallic impurities enter the material during crushing. Case studies demonstrate that using ceramic double-roll crushers can reduce iron content in cathode materials from over 100 ppm to below 5 ppm. Precise…

In heavy industries such as mining, metallurgy, and building materials, material crushing is a critical step in the production process. As an important crushing equipment, the large-scale double-roll crusher plays an indispensable role with its unique working principle and performance. Large Double-Roll Crusher: The Modern Industrial “Material Crushing Expert” Its core function lies in improving efficiency and enabling controlled crushing of hard materials. Through two counter-rotating rollers and the powerful compressive and shearing forces they generate. The crusher rapidly breaks down fed materials such as ores, rocks, and coal chunks into the required particle size. Compared to other crushing methods, the double-roll crusher offers significant advantages, including uniform product size, low over-crushing rate, stable and reliable operation, and easy maintenance. This characteristic makes it widely applicable in various industrial scenarios: in mineral processing plants. It provides raw materials of qualified particle size for ball mills; in cement production lines, it handles the primary crushing of raw materials like limestone; in the chemical and power industries, it is used for crushing fuels such as coke and coal. By mechanizing and automating material crushing, the large double-roll crusher significantly enhances industrial processing efficiency, reduces energy consumption and labor costs, and serves as…

As an efficient and reliable crushing equipment, the double-toothed roller crusher plays a crucial role in modern industrial production. Its core function lies in the precise crushing and particle size control of large chunks of medium- and low-hardness materials. Double-Toothed Roller Crushers: Efficient and Reliable Equipment for Modern Industrial Crushing In industries such as coal, metallurgy, chemical engineering, building materials. And mining, it is primarily used for the primary or intermediate crushing of raw materials. Through the splitting, shearing, and crushing of materials by two counter-rotating toothed rollers, it effectively reduces raw ore, coal, limestone, coke, and other materials to the required uniform particle size. This process not only prepares the materials for subsequent screening, washing, grinding, or smelting operations but also directly enhances the efficiency and stability of the entire production line. Compared to other crushing equipment, the double-toothed roller crusher offers significant advantages such as a compact structure, low over-crushing rate, relatively low energy consumption, and easy adjustment of the discharge particle size. It produces more cubic-shaped particles that meet specifications while reducing the proportion of powdered products, thereby making outstanding contributions to enhancing product value, lowering energy consumption, and reducing maintenance costs. Therefore, the double-toothed roller crusher…

The ore materials crusher (double-roll crusher) excels in the field of mineral material crushing, particularly suited for medium and fine crushing operations of medium to low hardness ores. It functions like a precision surgical scalpel. 1. Working Principle The double-roll crusher generates high-pressure squeezing forces ranging from 50 to 200 MPa through two counter-rotating rollers (smooth or toothed surfaces). This force draws ore into the gap between the rollers, where it undergoes compression and shear crushing. Under the influence of friction, the material is pulled into the crushing chamber, progressively crushed under pressure, and finally discharged through the roller gap. 2. Advantages High-Pressure Roller Mill Technology (Core Flagship) Intelligent Control System Wear-Resistant and Material Technology Structural Innovation and Multifunctional Design Environmental Protection and Energy-Saving Technology 3. Comprehensive Product Range Jaw Crusher (Primary Crushing) Cone Crusher (Secondary Crushing) Impact Crusher (Secondary/Fine Crushing) Double Roll Crusher (Secondary/Fine Crushing) Sand Making Machine, etc. 4. Technical Features – Utilizes advanced crushing technology – Rational structural design ensures stable operation – High crushing efficiency with uniform product particle size – Superior wear-resistant components for extended service life 5. Application Scope Metal ores: Gold, silver, copper, iron, lead-zinc, etc. Non-metallic ores: Limestone, granite, marble, etc. Construction…

stone aggregrate quarry crusher, also known as double-roll crushers, have become core equipment for modern quarries to reduce costs and increase efficiency due to their four major advantages: high efficiency and energy savings, precise particle size control, easy maintenance, and environmental compliance. They are particularly suitable for medium and fine crushing of medium to low hardness stone materials (≤200MPa). Replacing multi-stage crushing processes can significantly simplify production lines and enhance economic benefits. 1. High Efficiency and Energy Savings, Reducing Overall Costs High Output with Low Energy Consumption The double-roll crusher employs a dual-roll synchronous compression principle, achieving efficient crushing through high-pressure material layer pulverization (50-200MPa). Single-unit hourly output can reach 5-400 tons. Compared to traditional multi-stage crushing processes (jaw crusher + cone crusher), energy consumption is reduced by 30%-45%. Electricity consumption per ton of crushed material is only 0.7-1.2 kWh, saving hundreds of thousands of yuan in annual electricity costs. Low Maintenance Costs Roll liners made of high-chromium manganese steel or composite wear-resistant alloy (hardness HRC ≥ 60) ensure a **≥2-year** lifespan, with replacement costs only 1/3 that of standard hammerheads. Modular design enables rapid liner replacement within 1 hour, reducing annual maintenance expenses by tens of thousands of yuan….

+86-18703839693

+86-18703839693